BESTONE Plastic Injection ZI de la Tuilerie, 3 rue de l’industrie - 01100 ARBENT, France | +33 (0) 474 816 406 - com@bestone-france.com

BESTONE Plastic Injection ZI de la Tuilerie, 3 rue de l’industrie - 01100 ARBENT, France | +33 (0) 474 816 406 - com@bestone-france.com

At BESTONE, the pursuit of efficiency is a daily commitment.

Every team member takes ownership of the quality tools and requirements defined from the very start of a project through to the delivery of the final parts.

Our quality management system, certified ISO 9001:2015, is built on clear, controlled, and proven operational processes. It is driven by a simple philosophy: placing each individual at the heart of responsibility, rigor, and excellence.

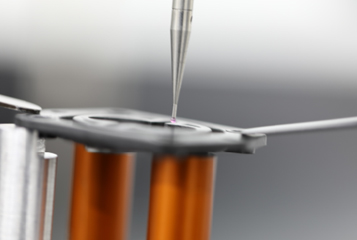

Comprehensive Quality Control Expertise

From the beginning of each development phase, we apply a structured approach tailored to the product and to the quality requirements associated with its application.

A thorough risk analysis is systematically carried out, including :

Quality Integrated at Every Stage

Each member involved in the production chain is accountable for quality.

Our production systems include real-time quality monitoring and statistical tools that track process evolution and ensure continuous stability.

Operators work with a digital monitoring system that allows them to record, depending on the required control level: